Conflux modernizes heat exchange solutions for aerospace, defense, and automotive industries with advanced simulation and additive manufacturing.

Michael Fuller spent 15 years as a design engineer in the European motorsport industry before founding a company that creates additively manufactured heat exchange technology. As he puts it, the concept for Conflux Technology was a classic case of sitting around a table with beers, pizza, and lots of ideas. His extensive experience with and understanding of thermal management challenges in high-performance systems helped him reimagine heat exchanger design. Today, his Australian-based company’s approach centers on the premise that geometry dominates heat exchanger performance, and additive manufacturing offers the necessary geometric freedom to improve performance and efficiency.

“Heat transfer is ubiquitous — we’re talking about the physical embodiment of the first law of thermodynamics,” said Fuller. “All machines need to manage heat to continue operations, and the energy required to manage that heat represents a massive opportunity for efficiency improvements.”

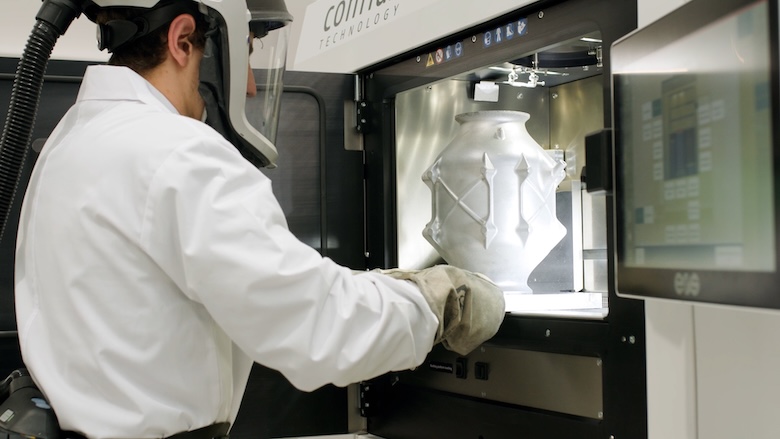

Conflux selected laser powder bed fusion (LPBF) as its primary manufacturing technology. The process involves laying down precisely sized powder particles in thin layers, then using laser scanning to selectively melt material according to 3D model specifications. Layer by layer, the process builds complex internal geometries with high resolution and thin-wall structures that would be impossible to machine or assemble conventionally.

Vertical integration drives innovation

Conflux operates what Fuller describes as “an inch wide, mile deep” company, maintaining a tight focus on heat transfer while vertically integrating across the entire development and production process. His 55-person team includes specialists in multiphysics simulation, CAD modeling, additive manufacturing process engineering, and quality systems — all working in cross-disciplinary project teams.

“There aren’t many off-the-shelf solutions to the problems we encounter,” said Fuller. “We have solutions teams that interface with customers early in their curiosity journey, helping them understand their problems through boundary conditions and packaging constraints, and what a solution based on Conflux could look like.”

The company offers two distinct approaches: configured solutions based on existing product families that can be adapted to specific boundary conditions, and custom solutions for unique applications. Additive manufacturing provides Conflux with a crucial advantage in both cases, allowing for design modifications without tooling implications. Fuller noted an aerospace customer application as an example.

“They doubled the pressure requirements after we already designed and manufactured prototypes to the original boundary conditions,” he said. “After four or five days of redesign and simulation, we went back into production on the same machine and produced components that could withstand double the pressure. Those opportunities just aren’t available with traditionally manufactured heat exchangers.”

This story is an excerpt from Design World. Click here to read the full story.