Manufacturers are managing greater volumes of data, growing product complexity and increasing pressure to deliver reliably. This white paper explains how closed-loop manufacturing connects digital information with real production activities, helping teams work with clearer visibility, better coordination and more predictable outcomes.

What You’ll Learn

- Why today’s manufacturing environment requires closer coordination between design, planning and production.

- How closed-loop manufacturing aligns as-designed, as-planned and as-built data for more consistent results.

- How the digital twin and digital thread support clearer insights and better decisions.

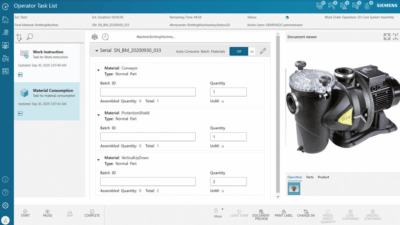

- The role of Manufacturing Operations Management (MOM) in linking PLM, automation and shop-floor systems.

- Why unified data and real-time feedback help identify issues earlier and improve overall process reliability.

Your download is sponsored by Siemens.