By Janine Love

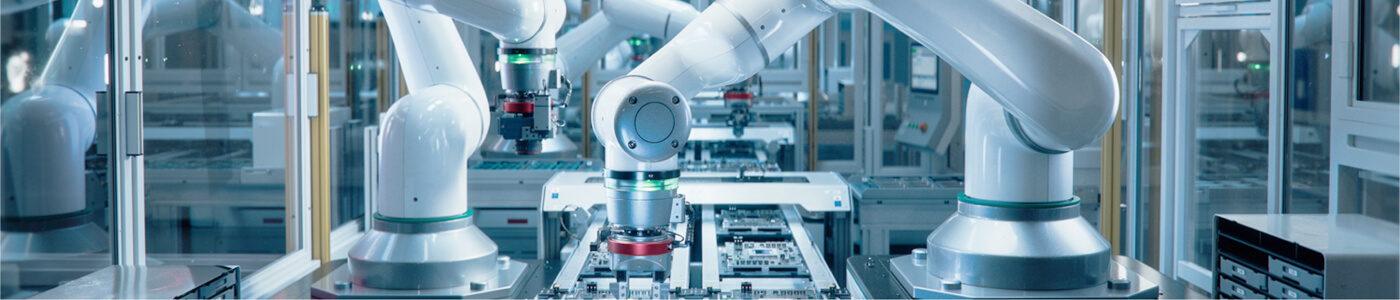

Manufacturing productivity has long benefited from automation, with factories regularly incorporating robotics and software-controlled equipment into their production lines. Many argue that factories could realize even greater efficiency gains with an open architecture for industrial automation. Software-defined manufacturing (SDM) is a growing area of interest, and it may be a method to enable technologies including artificial intelligence (AI), robotics automation, and data analytics.

A recent white paper, Software Defined Manufacturing: Enabling Industrial Automation aims to explain the basics of SDM, how it relates to the concept of the “digital twin,” and how it can be enabled by the efforts of the Open Process Automation ForumTM (OPAF) and other industry-standards bodies. The paper also reviews an application example of the smart factory, as well as some of the interconnect products and technologies that enable industrial automation and chart a path to the future of software-defined manufacturing [1].

What is Software-Defined Manufacturing?

SDM includes a layer of software that oversees all manufacturing processes, from initial building of parts to final assembly and testing. The necessary hardware includes sensors, cameras, and robots throughout the factory that feed back data into the control hardware and application software. The aim is to optimize the manufacturing process, making it more flexible to support product changes and prototyping.

The critical difference between SDM and traditional hardware-centric manufacturing is the ability for operators to have a unified view of the entire production floor. Instead of optimizing individual hardware systems for a particular task, OEMs can now also optimize the entire production line, from build, to assemble, to test [2].

Benefits of an Open Automation Ecosystem

An open automation ecosystem allows OEMs to combine best-in-class components and software from a range of suppliers rather than a single vendor. This allows flexibility in choice of supplier, simplifying service and process automation, and implementing control logic across the factory—a key enabler for SDM and allowing IT services to track and trace throughout the factory [3].

In addition, standard interfaces enable OEMs to swap out existing components with new ones. This can shorten engineering and commissioning time, and modularity reduces costs during process scale up. All of these benefits can improve total cost of ownership for automation equipment in manufacturing facilities.

Enabling Products

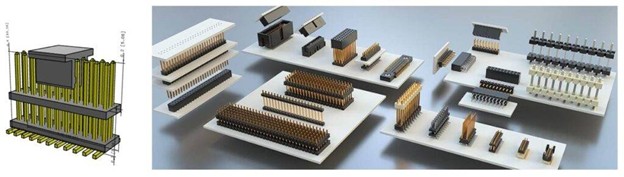

Many industrial automation system designers choose Samtec’s Tiger Eye™ connectors, specifically series TFM/SFM, because they are proven for use in small, high-reliability, high-cycle, rugged applications [4]. Tiger Eye connectors can be equipped with additional ruggedizing options such as screw down, weld tab, and solder nail. In addition to being part of Samtec’s Sudden Samples program, TFM and SFM Tiger Eye products are available from Samtec’s Reserve® program, shipping quantity orders in 1 day.

Another popular product to support industrial automation systems is Samtec’s board stacking connectors, where header and socket systems are available in a variety of pitch, density, stack height, orientation, and other standard or modified options [5]. For instance, post height and body positions are specified in 0.13 mm increments, as part of the standard ordering process. Series FW micro board stackers, for example, mate with CLP low profile, dual-wipe sockets with up to 50 pins per row.

Samtec’s industry-leading expertise in rugged/power and high-performance interconnect systems, combined with on-going Extended Life Product™ and Severe Environment Testing initiatives, enables quick-turn, cost-effective options for the performance, reliability, and durability demands of industrial automation applications, including enduring high vibration, high power, and high mating cycle systems in small form factors.

For more information contact 1.800.CALL.TTI and visit Samtec at TTI.

References

[1] Software Defined Manufacturing: Enabling Industrial Automation – White Paper

[2] Demystifying Software-Defined Manufacturing – Bright Machines

[3] Open Automation: Where Things Stand in 2024 | Automation World

[4] Micro, Rugged Industrial Connectors: Do They Exist? – The Samtec Blog

[5] Using Board Stacking Connectors in Industrial Applications – The Samtec Blog

Sponsored Content by TTI