Dassault Systèmes has sponsored this post.

Manufacturing is the backbone of many global economies, but supply chain disruptions, market volatility, and increased global unrest have challenged the industry. In product development, the biggest challenges product developers face today in getting products to market lie in manufacturing. A recent Tech Clarity eBook, The State of Product Development: 7 Trends Shaping Product Innovation, indicates that the top two product development challenges globally are supply chain disruptions/market volatility (74%) and design-to-manufacturing handoffs (60%).

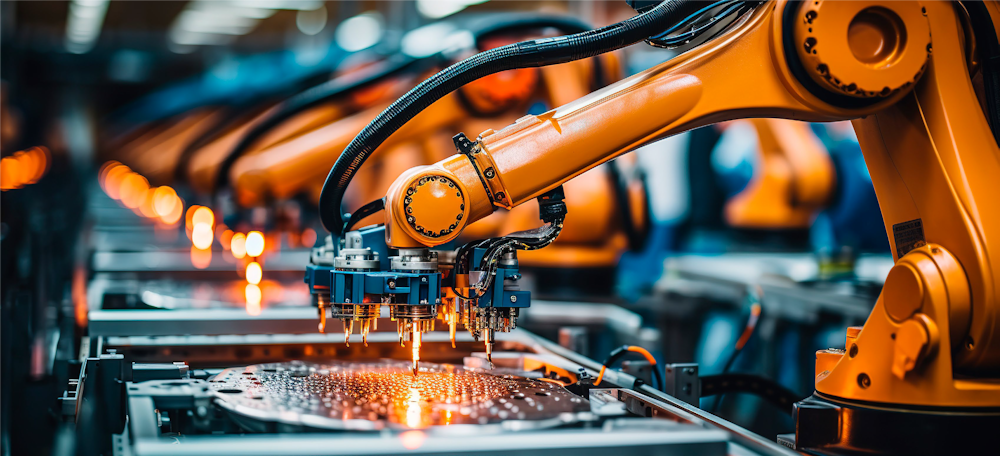

In response to these challenges, the manufacturing sector is undergoing a profound transformation as Industry 4.0 technologies reshape production processes and business models. Automation, artificial intelligence (AI), and advanced connectivity are redefining skill requirements, compelling companies to rethink how they attract, train and retain workers. For industry leaders and decision-makers, workforce resilience is more critical than ever.

Here are five key trends driving workforce resilience and preparing manufacturing teams for the future.

1. Upskilling and reskilling programs

As Industry 4.0 advances, technical skills have become essential across all levels of manufacturing. Projections show that demand for technical skills could increase by 50% in the next decade, while manual labor demand may decline by 30%. To address this gap, manufacturers are prioritizing upskilling initiatives.

Integration of STEM education: Programs starting as early as high school can familiarize students with robotics, data analytics and machine operations, preparing them for advanced technical roles.

Apprenticeships and on-the-job training: These provide workers with hands-on experience, ensuring they are proficient in evolving technologies.

Stackable certifications: Short-term, targeted courses allow workers to build skills incrementally, aligning their abilities with new demands.

Companies investing in reskilling are not only bridging the gap in technical expertise but also boosting morale and retention, ensuring that employees feel valued and future-ready.

2. Attracting and diversifying talent

Labor shortages pose a significant challenge, with 45% of manufacturers admitting they’ve declined business opportunities due to insufficient workforce capacity. Companies must rethink how they attract talent, focusing on underrepresented groups and non-traditional labor pools.

Diversification initiatives: Actively targeting women and underrepresented minorities can tap into a larger talent pool. For instance, Nebraska’s goal to increase the share of women in manufacturing highlights a shift toward inclusion.

Awareness campaigns: Efforts such as “Creators Wanted” educate potential workers on the opportunities in advanced manufacturing, showcasing modern, technology-driven environments that challenge outdated perceptions of factory jobs.

Community-focused outreach: Programs that bring manufacturing career opportunities directly to schools and communities can spark interest among young talent early.

Broadening recruitment approaches can help manufacturers build a more dynamic workforce while simultaneously addressing critical shortages.

3. Enhancing workforce infrastructure

Talent acquisition efforts are incomplete without adequate infrastructure to enable workforce participation. Affordable housing, accessible childcare and transportation support are essential in attracting and retaining workers, particularly in rural manufacturing hubs.

Housing initiatives: States such as South Dakota have allocated funds to expand workforce housing, facilitating easier relocation for employees.

Childcare support: Tax incentives for employers building childcare facilities or providing subsidies for employees help remove common barriers for working families.

Community investments: Infrastructure improvements in manufacturing-rich areas create a more sustainable talent ecosystem.

By addressing these foundational needs, manufacturers create environments where workers can thrive, supporting long-term labor market participation.

4. Leveraging technology for workforce engagement

Technology is revolutionizing not only products but also the way teams operate. Automation, data dashboards and augmented reality (AR) tools are reshaping daily workflows, creating safer and more engaging environments for workers.

Predictive maintenance: Real-time monitoring systems detect issues before they occur, enhancing equipment reliability and reducing worker downtime.

AR for training and repair: Technicians equipped with AR devices can access step-by-step repair guides overlayed on actual machinery, quickly building proficiency and confidence in their tasks.

Workplace optimization: Technologies that track and manage inventory or streamline operations allow workers to focus on high-value tasks, fostering job satisfaction.

These advancements reduce errors, boost efficiency and create an environment that aligns with the aspirations of a tech-savvy workforce.

5. Sustainability as a workforce driver

Sustainability is no longer just a corporate responsibility — it is an asset in attracting and retaining talent. Employees increasingly value organizations that prioritize environmental stewardship and green initiatives.

Green factories: Facilities using renewable energy and smart resource management demonstrate leadership in sustainability.

Waste reduction: Technologies like 3D printing minimize material waste, aligning with global sustainability goals.

Corporate commitment: Communicating sustainability milestones and emphasizing eco-responsible practices bolster employee pride and attract like-minded talent.

Sustainable practices not only position companies as industry leaders but also foster a sense of purpose among workers, cultivating loyalty and collaboration.

The bottom line

Building a resilient workforce in the Age of Industry 4.0 requires a multi-faceted approach. Upskilling employees, diversifying talent pools, investing in infrastructure, leveraging technology and prioritizing sustainability are essential strategies for manufacturers aiming to remain competitive.

By aligning workforce development with technological advancements and community needs, industry leaders can create an adaptable, forward-thinking labor force ready to thrive in this era of transformation. Now is the time to empower workers, and in doing so, secure the future of manufacturing.

To learn more, visit Dassault Systèmes.