A short circuit fault that occurs in the blink of an eye can cause damage that lasts hours, weeks, or even a lifetime. In a data center, for example, a short circuit fault can send energized cables whipping around racks of servers that could take months to replace. And in a factory, the same scenario could lead to fires, employee injuries, and even death. Cable cleats minimize those risks by restraining one or more cables against axial, lateral, and torsional forces. They’re ideal for ensuring that installations comply with NEC 392.20(C), which requires single conductors to be securely bound in circuit groups.

What are cable cleats?

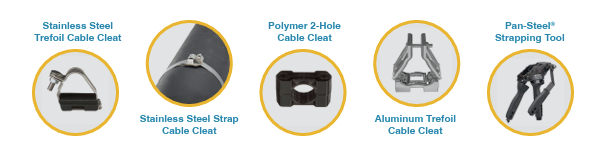

A: Cable cleats ensure that cables remain contained in the event of a short circuit fault to minimize disruption and damage to people and property. They utilize stainless steel strapping with heads or buckles, hinged designs, flame-resistant polymers, aluminum, locking nuts, and corrosion resistant hardware to fix cables onto trays and other surfaces far more securely than alternatives such as Velcro and conduit clamps. Cable cleats are available to support a variety of configurations, such as single/multicore, trefoil, and quadrafoil.

Where are cable cleats used?

A: Cable cleats are ideal for any installation where high power cables are located near people, equipment, or both. The voltage level is irrelevant. In fact, quite often the highest fault levels can be seen in low-voltage installations. Common examples include data centers, utility tunnels and vaults, refineries, power plants, factory floors, and subways— potentially including ones funded by the U.S. Infrastructure Investment and Jobs Act (IIJA).

In addition to helping installations comply with NEC 392.20(C), cable cleats are also ideal for conforming with local building codes—such as California’s seismic requirements—and meeting insurance policy conditions. Cable cleats help electrical contractors avoid rework by ensuring that their installations meet all those customer, code, and other requirements from day one.

Finally, by helping ensure a safe workplace, especially in confined spaces such as underground vaults, cable cleats can minimize employee downtime. That helps businesses such as factories and utilities cope with the chronic shortage of industrial electricians and other skilled workers.

Is there a cable cleat standard?

A: IEC 61914:2021 is the latest, most comprehensive, and globally accepted cable cleat design and testing standard— including North America. Initially published in 2009, this standard covers key requirements such as resistance to impact, corrosion, and UV, as well as temperature rating, axial load, and more. In the process, IEC 61914 helps electrical contractors and other professionals make an informed, apples-to-apples comparison between different vendors’ cable cleat products.

Since 2019, Panduit has been a member of the IEC committee responsible for overseeing the IEC 61914 standard. This role ensures that Panduit and its customers remain ahead of the curve, including the products designed to meet the latest standards requirements. Customers also benefit from Panduit’s expertise with stainless steel strap cleats. Panduit specialists have had experience with the IEC cable cleat standard since its inception in 2009 and, before that, with the BS 50368:2003 standard.

To provide additional guidance for electrical contractors and other professionals, two national standards bodies for the North American market have established a cable cleat task force. Both upcoming standards will be written using the current IEC standard as a guiding document and will therefore contain the same rigorous testing regimes and manufacturing requirements. It is hoped that both documents will be fully published within 12-18 months. This timeline could be particularly helpful for infrastructure projects funded by the IIJA because states and federal agencies will begin disbursing the majority of that money in 2023-2024.

How does the IEC cable cleat standard help meet NEC requirements?

A: NEC 392.20(C) covers the safety of the cable installations in cable trays, but it doesn’t specify how to protect against excessive cable movement in the event of a short circuit. IEC 61914 helps fill that gap by providing manufacturers and electrical contractors with additional, granular guidance. Examples include the testing methodology and process to ensure cable cleat reliability, including temperature rating, resistance to flame propagation, lateral and axial load testing, impact resistance, corrosion resistance, and resistance to electromechanical forces.

What are some best practices for choosing and installing cable cleats?

A: The Panduit Cleat kAlculator app for web-browsers, smartphones, and tablets makes it fast and easy to identify the right type of cable cleat and determine the correct amount of spacing for installation. Simply select the cable layout and then enter the peak short circuit current and cable diameter. The app will provide part recommendations, as well as the cleat spacing necessary to comply with IEC 61914.

For more information contact 1.800.CALL.TTI

To learn more, visit Panduit at TTI, Inc.

Sponsored Content by TTI IP&E Americas