By Rahul Garg, VP for Industrial Machinery Vertical Software Strategy, Siemens Digital Industries Software

Doing things the way they have always been done is no longer enough to manage rising operational costs, production process inefficiencies, and a tight labor market. Digitalization and automation are the game changers to navigate these challenges. Manufacturers can bolster their automation systems to guarantee adaptive and flexible production, helping their business stay profitable and competitive. Contrary to popular belief, modernization does not necessarily involve replacing every single piece of old equipment with shiny, new machines.

Most manufacturers have many legacy plants which operate a diverse pool of machinery. And factories that have successfully incorporated modern automation processes had antiquated equipment which lacked the more advanced capabilities of more modern machines such as IoT connectivity and AI integration. So, where did they start?

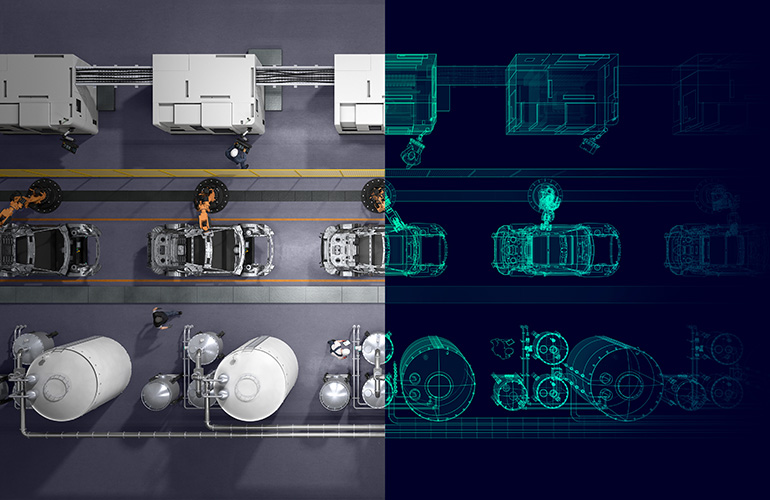

Achieving a more automated factory that is ready to face a volatile landscape starts with a plan. With a solid plan, manufacturers can more easily incorporate automation features into production lines. To guarantee harmony between old and new systems, manufacturers should look to the comprehensive Digital Twin. Utilizing the simulation capabilities of the comprehensive Digital Twin makes automation integration seamless and hassle free, enabling a wide range of resource-conserving testing capabilities and bringing agile, resilient operations onto the shop floor.

Starting small, starting flexibly

Beginning a digital transformation journey leads to growth through improved efficiency and increased profitability. Becoming a digital enterprise has the added benefits of increasing productivity, improving operational efficiency, and reducing costs. It also gives organizations a chance to upskill employees while improving worker job quality and pay. However, while enhancing the versatility of the factory comes with plenty of advantages, the investment may seem intimidating at first glance.

Fortunately, this is where the comprehensive Digital Twin – the foundation of digital transformation—comes in. The comprehensive Digital Twin is a virtual representation of a product throughout its entire lifecycle, from design and production to performance. It ensures end-to-end data continuity between all stakeholders enabling cross-domain collaboration, traceability, and closed-loop feedback.

As well, the production Digital Twin is a key component of the comprehensive Digital Twin and provides a great starting point for brownfields to begin their digital transformation journey. Leveraging the Digital Twin’s simulation capabilities, they can see impressive gains from more modern forms of automation in the digital world to determine what technologies can be introduced without much interruption to their existing processes or before making any significant investments. With the power of the Digital Twin and AI, implementing adaptive automation is a worthwhile venture.

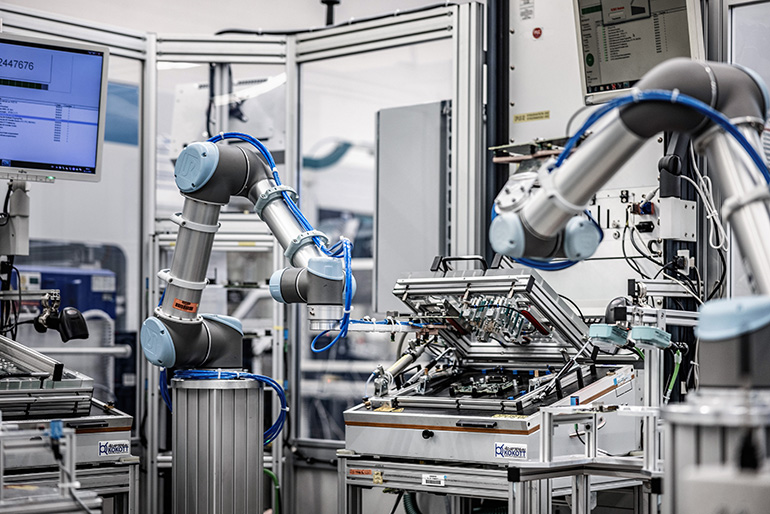

One of the key areas that companies can exploit for driving production efficiencies is with Robots. Manufacturers that are intimidated by a full upheaval of their factories can instead look to collaborative robots, also known as cobots, or robots that aid human workers during production. Cobots work as a conduit between manual and automated operations and can be easily introduced into a brownfield environment. Using cobots, brownfields can:

- Improve the efficiency and profitability of their production processes through defect detection, data collection, and error reduction

- Alleviate workforce woes by supporting skilled workers and reducing the need for repetitive tasks

- Increase flexibility and adaptability and ultimately lower costs through scalable solutions and easy reprogramming

Cutting costs with virtual commissioning

The question becomes how best to introduce Robots and Cobots in an existing factory? It is crucial to test how and where certain processes will work before integrating Cobots, new machines, or processes onto a more traditional shop floor. The Digital Twin of the factory creates an accurate, real-time virtual representation of their factory that is both comprehensible and accessible for workers across teams and disciplines. Equipped with the near-accurate representations of potential modifications, engineers and designers can explore and then validate prototype systems and production lines to ensure they are both more productive and safer for human workers on the shop floor.

Virtual commissioning and robot offline programming can significantly reduce the time and effort required to implement the latest automation processes into existing production environments. A Digital Twin empowers manufacturers to make informed decisions in the virtual world before investing in physical builds. A variety of trial runs of potential new systems can be done quickly without having to divert actual equipment from operations. On top of that, simulated verification can be completed sometimes within days, making it possible to have more optimized and flexible systems very quickly.

Once the manufacturing line is up and running, the Digital Twin can be enriched with ongoing, real-time data from factory operations. Enabling factories to simulate, predict, and optimize performance in real-time helps manufacturers anticipate equipment failures before they happen. This minimizes, or even avoids, costly downtimes as maintenance can be completed before any critical errors occur.

With the Digital Twin simulating production systems, manufacturers can focus on safely and effectively incorporating these machines into their more manual production lines. Virtual commissioning enables the factory to forecast human interactions with automated systems, improving ergonomic design and safety. By deploying these factors, brownfields have been able to introduce new, state-of-the-art equipment only where needed, quickly and at low cost.

Training robots quicker in virtual classrooms

When working in tandem with AI, the Digital Twin can also accelerate robot training and programming through the industrial metaverse, a virtual space that expands on the physical world which fosters efficiency, productivity, sustainability, and connectivity. The industrial metaverse is still new, but its training capabilities for robots are unparalleled.

Taking full advantage of the industrial metaverse’s simulation abilities, manufacturers can create immersive settings that perfectly imitate physical factories and production lines. In this virtual classroom, robots can practice tasks, address common challenges, and develop problem-solving skills in just hours, rather than months or even years.

Unlike physical environments where engineers are limited by both time and tangible constraints, simulated environments provide settings with no restrictions, enabling robots to learn to tackle even unanticipated problems. Additionally, since the virtual classroom is digitally constructed, creating training scenarios is quicker and more cost effective than setting them up in the real world.

Virtual classrooms are not only reducing risk and operational costs but also could potentially prepare robots to create tomorrow’s products. The Digital Twin and industrial metaverse aids deployment of automation systems with dramatically reduced setup times, meanwhile, the enhanced adaptability of AI-powered tools aids the versatility of product lines in response to changing market demands.

Bringing in AI to accelerate towards the future

Once the Digital Twin is well integrated into the factory, AI can supercharge the factory’s operations. Solutions like AI Expert Toolbox can address AI makers as well as AI users. AI makers have dedicated know-how in building AI models. AI Expert Toolbox supports bringing and operating these models on the shop floor in an industry-grade environment.

On the other side for AI users, there will be dedicated services like Citizen-AI, which combine specific AI applications and allow everyone on the shop floor to run AI-based solutions with the help of improved user interfaces, understandable monitoring, automated model retrain, and more.

Using AI together with the Digital Twin, organizations have crafted techniques that improve robot versatility. Solutions like SIMATIC Robot Pick AI can transform standard industrial robots into complex, agile machines. Pick AI harnesses both AI and Digital Twin capabilities. Trained on synthetic data and through computer visions, Pick AI prepares robots to handle unpredictable tasks with over 98 percent accuracy.

Keeping it cheap and simple

The Digital Twin has helped manufacturers make massive strides in their journeys to accelerate modern automation and enhance resilient, adaptive operations. Using the Digital Twin, factories can gain new insights due to the combination of physics-based simulations with data analytics in a fully virtual environment. This makes it possible to realize innovations faster and more reliable, while also requiring significantly fewer real prototypes.

Leveraging the simulation abilities of the Digital Twin and AI, adopting innovative automation routines becomes seamless, hassle-free, and accessible while adding significant improvements in efficiency and productivity. Jumpstarting your factory’s digital transformation journey and reaping the rewards of automation is only a click away.

About the author:

Rahul Garg is Vice President for Industrial Machinery Vertical Software Strategy at Siemens Digital Industries Software.

As a customer-centric leader, one of Rahul’s great joys is helping simplify complex problems for customers and enabling success by delivering powerful, effective solutions that support small and mid-sized businesses.

Throughout his career having worked at three start-ups and now a large enterprise, Rahul has worked closely with SMBs and in technology-led industries to overcome key challenges and drive revenue growth with strategic solutions, smarter services, and better business practices.

Sponsored Content by Siemens Digital Industries Software