Insights from the Stratasys Media Day at Rivian’s Engineering Center in Plymouth, MI.

(Example metal stamping prototypes from Rivian, 3D printed in ASA. IMAGE: Author.)

“We’re on our way to Motor City!” the flight attendant announces as our plane taxis to the runway at Pearson International Airport in Toronto. It’s a short flight to Detroit (less than an hour) but it gives me time to reflect on that nickname and whether it’s still apt.

Google autocompletes ‘detroit automotive industry’ with ‘collapse’ and the subsequent search results include articles about its rise and fall, a Wikipedia page on the 2008-2010 auto industry crisis, and an “explain like I’m five” subreddit thread titled simply, “What happened to Detroit?”

To say the answer is complicated would be an understatement, but whatever explanation you choose, there are at least two undeniable truths.

First, the auto industry is baked into the DNA of Detroit and Michigan more broadly. On the cab ride to my hotel in Plymouth, I pass Henry Ford Health as well as seemingly endless parade of job shops and suppliers spanning the entire value chain. Advertisements for technical training and shift work are second only to those for ambulance chasers personal injury lawyers in frequency (though it is a distant second).

Second, and more importantly, however you tally up the factors leading to the shakiness of the Motor City moniker today, technology will surely be on the list. The U.S. auto industry has been playing catch-up on that front since the ‘70s. Only in the last decade or so have we started to see it reemerge as a technology leader, not just inside the vehicles rolling off the assembly line, but on the line itself and in manufacturing as a whole.

That’s why I’m here: to attend a Media Day at the Rivian Engineering Center in Plymouth, MI, cosponsored by Stratasys, and to learn how additive manufacturing (AM) fits into the future of automaking.

Here’s what I saw.

Rivian Impressions

The first note I write down upon entering the building is, “software company vibe” and it holds up until we start the actual facility tour. There are rows upon rows of desktop computers, interspersed with shipping containers that serve as meeting rooms in the large open-concept space. Murals of rugged landscapes adorn the walls: mountains and forests evoking treks through the Pacific Northwest. The first real indicator that this is a car company is the set of bay doors on opposite sides of our conference room.

That’s quickly reinforced as the presentations get underway, with an introduction that frames Rivian as an American Automaker, first and foremost. The company is launching its new midsize—the R2—next year, which it sees as the next chapter in the history of US automotive manufacturing.

Before becoming the Engineering Center, Plymouth was Rivian’s original HQ. Its first manufacturing facility is located in Normal, IL and a second just recently broke ground in Stanton Springs, GA. Even though its current headquarters are in Irvine, CA, Rivian still evokes a sense of continuity with the legacy of automaking in the American heartland. Nevertheless, there is something indelibly tech-y about this introduction. Maybe it’s the fact that a representative of the company cites Rivian’s software stack (of all things) as its “secret sauce.”

Additive automotive manufacturing

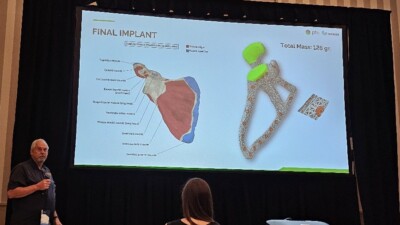

Now comes the real reason we’re here: Rivian’s use of Stratasys’ 3D printing. Jonathan Dankenbring, Rivian’s senior manager for prototype manufacturing, walks us through his operation virtually and (later) physically. He tells us about his experience leading Rivian’s prototype manufacturing team, which started seven years ago with a couple of CNCs and a single desktop 3D printer he brought from home. Today, his department includes a DMG MORI 5-axis mill as well as 28 Stratasys machines for selective laser sintering (SLS), stereolithography (SLA), and Selective Absorption Fusion (SAF).

Dankenbring tells us that he and his team have received six thousand requests in 2025, 86% of which have been completed in five days or fewer in Q4 of this year. Jared Beck, additive manufacturing manager at Rivian’s production plant in Normal, IL tells us you can find an additive part “every fifteen feet” when you walk through the 1.1 million-square-foot facility, which adds up to a lot of 3D printing. In short, Rivian is a manufacturer that is heavily invested in AM. But here’s another key statistic: 38% of those six thousand requests Dankenbring highlighted were for jigs and assembly aids.

Examples include ten thousand small shims for panel alignment made with SAF, soft jaw replacements (“We haven’t machined those in four years,” Dankenbring says.) and 35% of Rivian’s stamping prototypes, which can apparently bend steel plates up to 2mm thick.

“But where are the end-use parts?” the automotive media guys at the event want to know. They seem disappointed that we aren’t being shown examples of additive manufacturing for automotive components. It’s understandable, because they’re more interested in the end product than how it’s made, and 3D printing technology is mostly a novelty to them. But, as our tour gets underway, I think I’m already starting to see the bigger picture.

Stay tuned for Part 2: Inside Rivian’s prototype manufacturing.