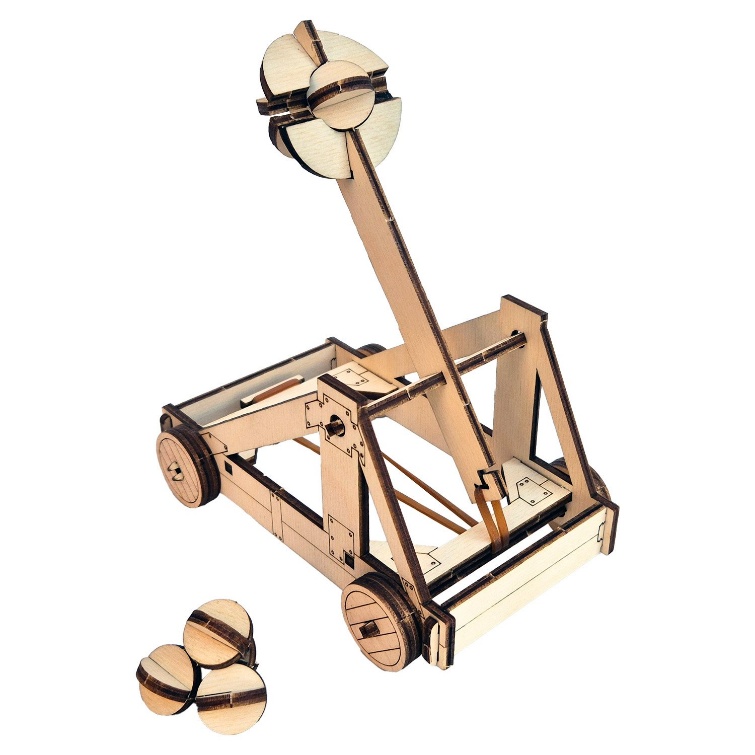

Estonian woodcraft company Artem Arbor designs and manufactures intricate laser-cut wooden toys and decorations with the aid of Solid Edge.

Siemens has sponsored this post.

In Estonia, craftsmanship has never been just about making products. The country’s forests, traditions and work ethic have shaped creative practices for generations. Artem Arbor, a small woodcraft company founded by two friends, sits firmly in that lineage. While the brand produces laser-cut wooden toys and decorative pieces, the story behind Artem Arbor is less about commercial scale and more about making things.

At the center of that story is Märt Tammisaar, who balances roles as both teacher and craftsman. “I’m a teacher, and I also have a small hobby company,” he explains, describing how Artem Arbor began as a passion project outside his day-to-day work.

The name Artem Arbor comes from the Latin for “art wood.” The company was never conceived as a high-stakes startup or a shot at instant financial success. Instead, it emerged from curiosity, collaboration and the kind of creative problem-solving that happens when people have the freedom to tinker. “I teach what comes before engineering — simple tools, woodcraft, metal craft and their machines — in the eighth and ninth grade. For example, they design their own key chain, and I cut it out with the laser using plexiglass.”

That tinkering mindset didn’t appear out of nowhere. Before stepping into teaching, Tammisaar spent summers doing physically demanding industrial work like “sewer” welding while getting exposure to CAD with the military.

The experience left him with a deep respect for hands-on skill and generally understanding the need for practicality in design. It also shaped how he approaches craft today. “It really helps you when you design something,” he says. “You know how something works and how this piece comes together with that one.”

This blend of practical knowledge and thoughtful design is visible in Artem Arbor’s products. The company focuses on objects that are tactile and intentional. The products reflect Estonia’s broader cultural relationship with nature and making, where craft is not nostalgia, but continuity.

New Iterations and New Products

Even small craft brands require strategy and adaptation. Artem Arbor has developed and iterated on many products over time, sometimes with surprising results. One of their most popular items — a miniature stable — was originally a side idea, not a flagship product.

“That was just a random thought. Someone liked stables and they were popular,” Tammisaar explains. “So, we did a stable, and it’s our most popular product, not the one that we started with.”

It’s a reminder familiar to many makers that the market responds to what resonates emotionally, not just what is clever on paper. “You may think one way, but the customer is the other,” he adds.

Artem Arbor’s goal has not been rapid expansion or high-volume manufacturing. Estonia’s market is small and the company intentionally looks beyond national borders to find a broader audience, but growth is measured differently. “You want a self-sustaining company… to be able to do what you want to do,” Tammisaar explains.

Sustainability, in this sense, means time to create, refine and explore. Time to collaborate. Time to maintain the machines, solve problems and keep the workshop running. As Tammisaar puts it, with a laugh, “I’m the one who makes the machines go. If there’s maintenance and there’s something wrong with it, then I’m the guy.”

Meanwhile, his business partner is the one who handles much of the day-to-day making and ideation. Their combined efforts have led to the creation of a micro-factory for their wooden widgets and toys. It’s a partnership that isn’t built on defined roles, but rather on trust and complementary strengths.

Designing with Digital Precision

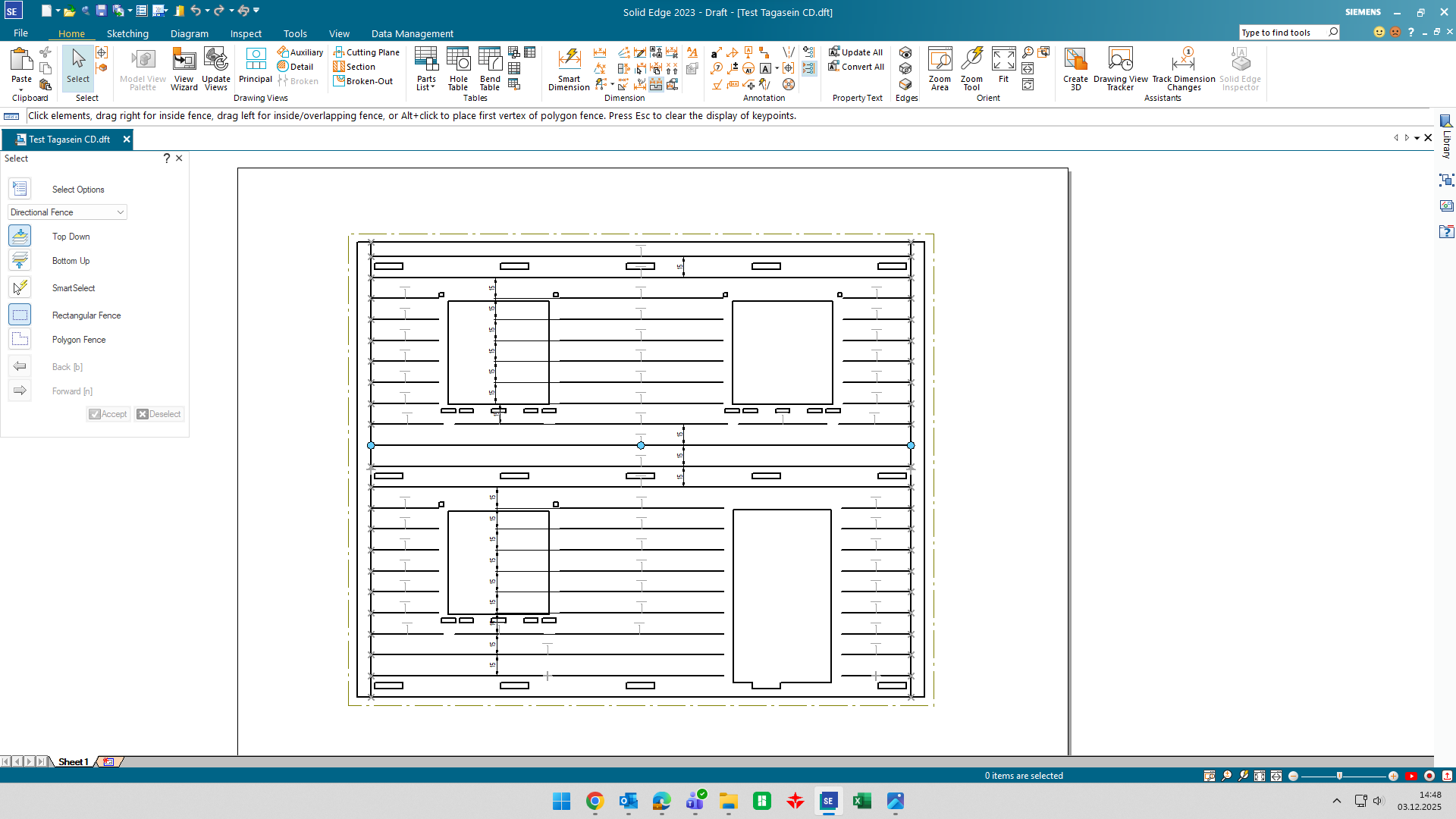

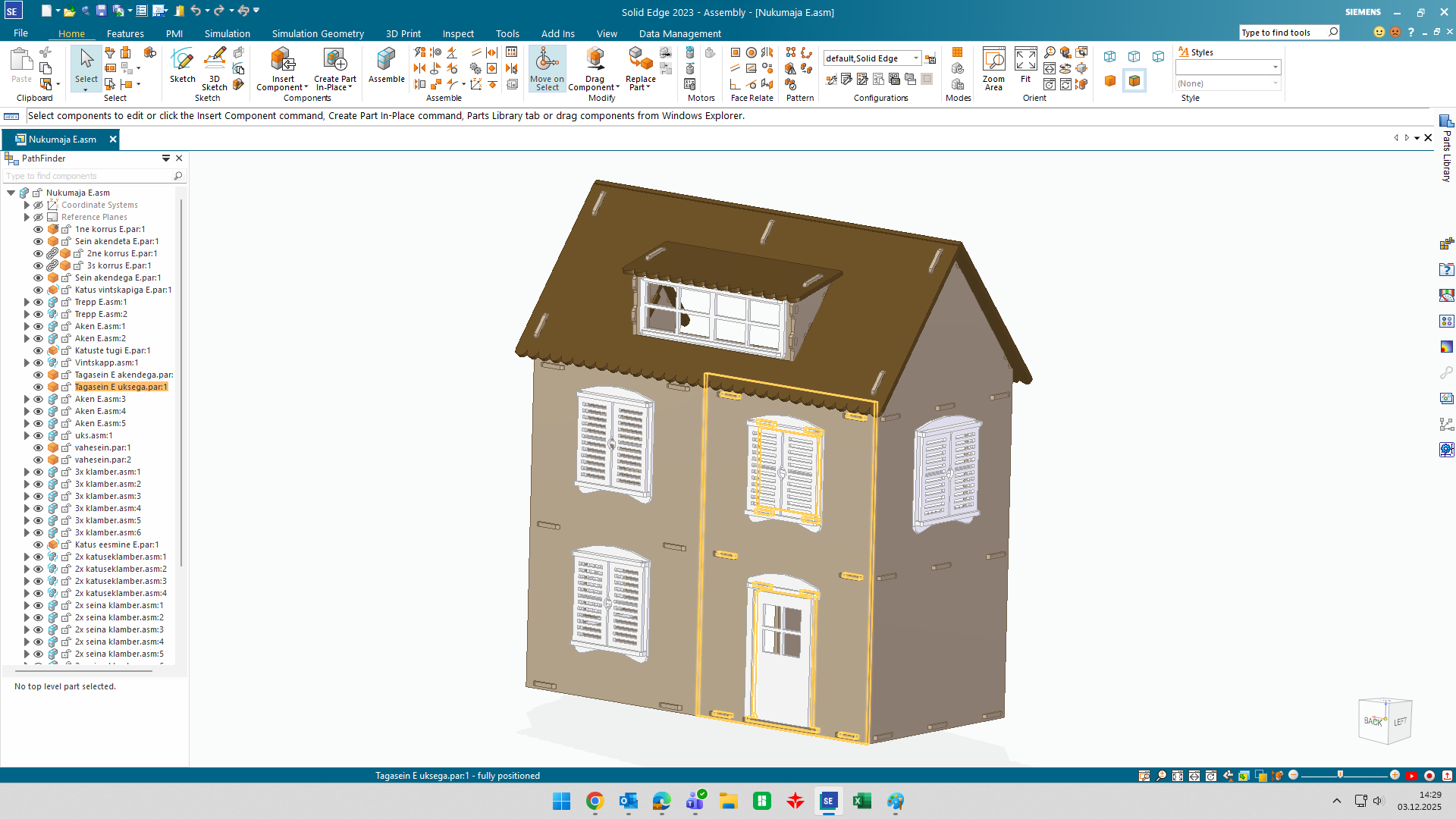

While Artem Arbor’s identity is rooted in traditional craftsmanship, digital design plays a quiet but vital role behind the scenes. Like many small businesses blending art and engineering, the team uses Siemens Solid Edge to visualize and refine concepts long before a single board is cut.

The software’s modeling environment allows them to move fluidly between idea and execution, iterating on tolerances, joinery and geometry digitally. Then with digital designs, they can easily mass produce their products on a CNC laser cutter. For a small organization, that precision shortens the gap between imagination and material.

What makes this approach valuable isn’t automation or making millions of parts, it’s control. Solid Edge’s combination of history-based and synchronous modeling lets Artem Arbor design like makers, not machine operators. The result are products that maintain a handmade soul while benefiting from engineering-grade accuracy and tools.

This collaborative approach extends to Artem Arbor’s relationship with its audience. The products feel personal because they are. They are shaped by the needs and curiosities of real people, carefully calibrated in small batches and designed to last. This is not factory production. It is something smaller and more deliberate.

Educating Leads to Good Business

Tammisaar teaches, designs, builds, repairs, experiments and adapts. His practice shows that craft can evolve without losing its grounding, and that independence in work is not only a financial condition, but a philosophical one.

Ultimately, that’s what makes Artem Arbor compelling. It isn’t trying to be something louder or flashier than it is. It is a small workshop making meaningful objects, shaped by the lived expertise of a team who has worked on making in both the digital and physical worlds.

“The last time we had the Estonian teachers conference, the shop teachers were at my place in school, and I had a little workshop where I showed them what we can do with CAD and lasers, which the other teachers would know well,” Tammisaar explains. “But I compiled all the things I did with TinkerCAD (for the younger students) and Solid Edge (for the older students) and compiled them into one room. There was 3D printed stuff, laser cut stuff, and then there was the CNC milled stuff, and their jaws dropped. They haven’t seen that much stuff done with machines in a school shop.”

As he builds both his business and his educational repertoire, Tammisaar seems to be hitting the sweet spot with digital and hands-on work. In the end, he embraces his teaching with a different perspective because he is using the same tools to both teach and grow his business.

Visit Siemens to learn more about Solid Edge for Startups program and the Solid Edge Maker Community edition.