It's not just laggy assemblies. Here are 6 reasons fasteners continue to frustrate CAD users—and how engineers can fight back.

If there’s one thing that CAD software should have solved by now, it’s fasteners. And yet, these simple, ubiquitous parts remain a frustration for many engineers.

Why don’t we have a single library of amazing fastener models? After eight years of building a fastener library from scratch, I think I know the answer.

My name is Peter Brinkhuis. After five years of working as a mechanical engineer, I noticed that my work could use some more automation. So I quit my job and founded CAD Booster, where we create user-friendly software (and other tools) for Solidworks. I’ve created a drawing automation add-in, an incredibly consistent fastener library and a tool to make working with fasteners fun again.

So what’s the problem with fasteners? The problem is there’s not just one problem. Fasteners are being held back by CAD performance, business models, withdrawn standards and more. But by understanding what we’re fighting, engineers can fight back—and win the battle for better fasteners.

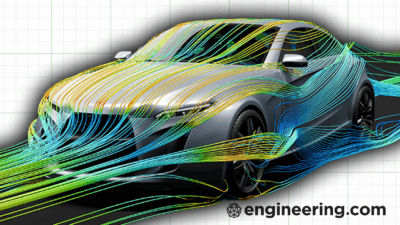

We’re fighting performance

A mechanical model is by definition an approximation of reality. How accurate that model should be is up to you and your employer.

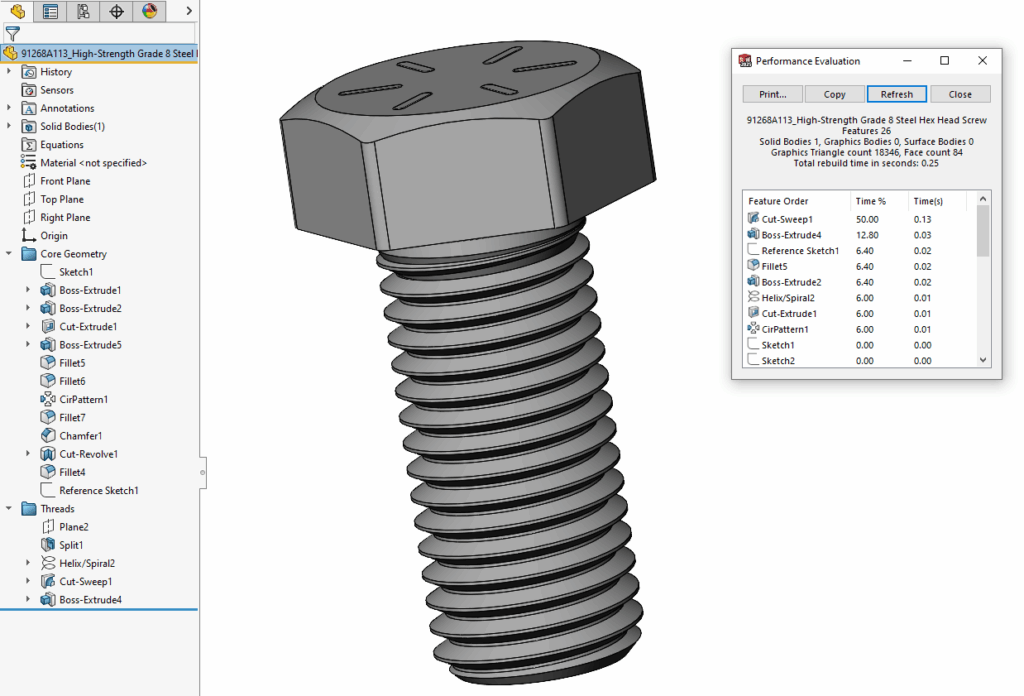

Do you want geometrically accurate helical threads modeled on all your bolts? Go ahead, but you’ll kill performance and make your colleagues want to pull their hair out. The supplier McMaster-Carr still includes helical threads in most of their models, unfortunately, and with a rebuild time to match: 0.25 seconds. Simplified models are 25 times faster.

I once debugged a large, slow assembly in Solidworks and found it was lagging due to four levelling feet with fully modeled threads. Once the threads were gone, the assembly got snappy.

But how far do you go? I stop at bolts that still look like bolts but that have no modeled threads or radii. I’ve also talked with a company that designs slaughterhouses, and they’ve resorted to only adding an attribute to a hole. Zero geometry, lots of speed, accurate BOMs—but not very lifelike.

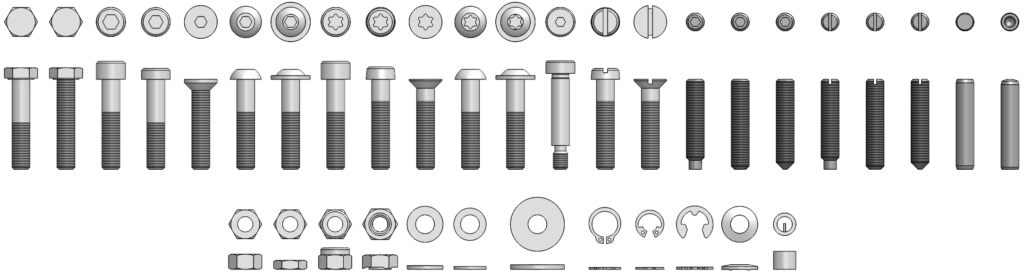

We’re fighting entropy

Every engineering company has a fastener library. They may start out using the Solidworks Toolbox, but at some point they’ll quit using that and start creating their own fastener models. How hard could it be, right? It’s just a sketch, a few dimensions, a revolve and a cut-extrude.

But then comes the request for consistency across all thousands of files or configurations. It would be great if bolt types were interchangeable without breaking mates. How about metadata? And how do the files appear in your BOMs? Does every material get its own file, its own configuration? Can you buy every size in every material? No task is trivial if you have to perform it 50,000 times.

And who’s managing all those fastener files? Is someone in charge (great for large companies) or can any engineer add a size (the reality of SMBs)? I’ve seen libraries with fastener sizes like M7x22; sizes that you cannot (and should not) buy anywhere.

We’re fighting standardization organizations

I have worked my way through the PDFs of 60+ DIN and ISO standards, and one thing I learned from reading between the lines is that these standards are not written for the engineer. They are written for the manufacturer. Things have gotten better with the ISO standards, but the old DIN standards were bad.

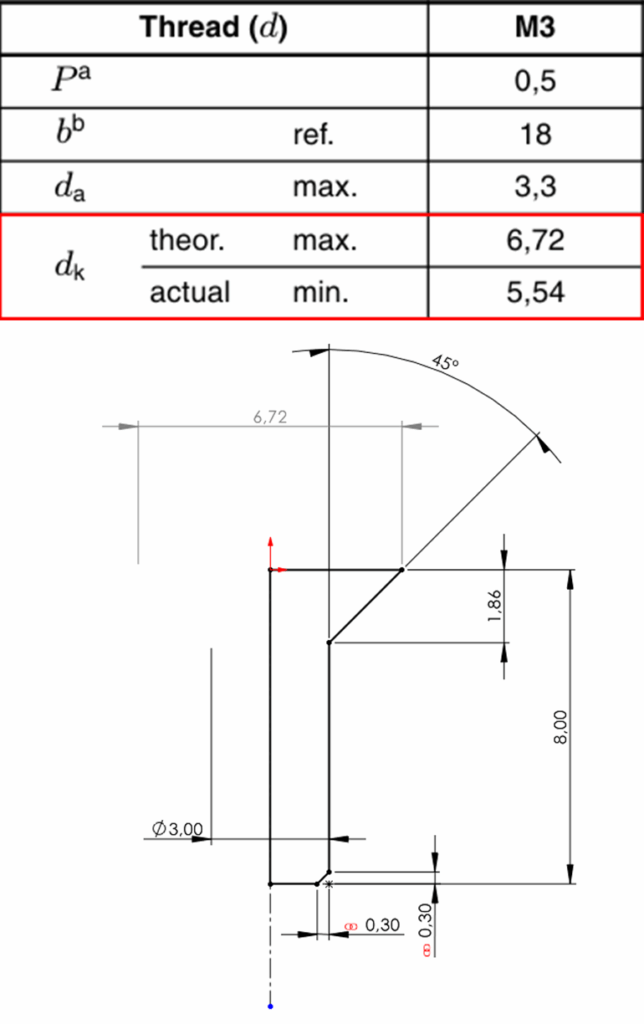

For most fastener standards, the shape is not fully defined. Manufacturers get lots of leeway, especially with the under-head shape of bolts. Drawing those bolts in CAD is impossible because the shape is undefined. Countersunk ISO 10642 bolts only have a theoretical max head diameter and a minimum value, not a target value with a tolerance.

Standards are also written to fit on an A4 piece of paper, which is terrible if you want to copy the data from a long table that spans multiple pages (but that’s a whole different story).

We’re fighting ghosts

Most DIN standards for fasteners, like DIN 933 for hexagon head bolts and DIN 912 for hexagon socket head cap screws, were withdrawn 20 – 30 years ago. But engineers keep adding them to their designs, and shops keep stocking them, because purchasing doesn’t care what the current ISO standard is. So we’re stuck.

The only way out is to move forward. Stop using standards that were withdrawn decades ago and start using the ISO replacements. There are tiny differences, like the width across flats for hexagon head bolts size M10, M12, M14 and M22, so keep your eyes open. Lead engineers should take charge and the rest will follow. If you don’t know who the fastener police is at your company, it should be you.

And please stop using spring lock washers like DIN 127 and serrated washers. They are the 1950s idea of locking devices, but they just don’t work. Junker vibration tests show this, and DIN withdrew these standards without a replacement. Your fasteners will still come loose, so switch to Nord-Lock washers or a properly preloaded set of fasteners.

We’re fighting shops

If engineers don’t stop ordering withdrawn fastener standards, shops will keep selling them and manufacturers will keep making them. There’s no incentive for a shop to tell a purchaser “no” when the company is ready to buy a pallet of DIN 931 bolts. And a purchaser will never ask the engineering department to update their assembly just to comply with the latest standards.

So engineers need to take the lead. Ask for the latest standard and don’t budge at the first sign of resistance. Tell them Peter sent you.

We’re fighting business models

Consistency is valuable, so most CAD suppliers are happy to put fasteners behind a paywall. Solidworks has their Toolbox, which requires a Professional or Premium license, and it’s great until it’s not. Onshape does it better with their Standard Content, which is available to all users.

But how about sharing our fasteners? Send your Toolbox fasteners to a supplier without the proper license and your assembly breaks. I’ve seen situations where the supplier/contractor had to have the same exact Toolbox setup or the fasteners would break. How are we supposed to collaborate?

The end result is that CAD companies are holding our fastener libraries hostage. Skip a bill or downgrade your license and you lose access to a fundamental part of your engineering business. I think you should own your fastener library.

Now it’s your turn to fight

I’m honestly amazed that fasteners are so consistent all around the world. That means standards work, even though they are theoretical and they are written for manufacturers, not engineers.

But 3D models are implementations of those theoretical documents, and implementations are even harder. You can’t draw a bolt shape that isn’t fully defined, but you can buy a length that is not in the standard. I think that ISO should include fully defined fastener shapes in their standards from now on.

Every engineering company is different, so every fastener library will be built on different assumptions. You and your team should choose your path: build your own fastener library, buy one, or improve the existing one.

Fight for your fasteners. Take the lead, put in some effort, and the rest of the company will follow. Kick out the fasteners that don’t work, replace withdrawn standards, fight for consistency. And prepare to do it again in a decade.

About the author

Peter Brinkhuis worked as a mechatronics engineer before quitting his job to start CAD Booster, a software company that creates user-friendly add-ins for Solidworks. He is an engineer that works on intuition, so his ultimate goal is to create software that is intuitive to use. He writes about Solidworks, its API and its quirks.

Peter also runs Spotlight, a coworking space for entrepreneurs.