By Bjorn Sjodin, SVP Product Management, COMSOL

Computer modeling and simulation has been a cornerstone of engineering innovation for decades. For applications ranging from aerospace products to consumer electronics, companies have long relied on computational models to test ideas, predict performance, and guide product development. Simulation is, at its heart, a decision support tool: data goes in, knowledge comes out, and critical choices are made with greater confidence.

But while simulation is powerful, creating and running sophisticated multiphysics models typically requires specialized expertise and expensive computational resources. As a result, simulation engineers have played a central role in turning the physics into actionable insights. However, it is common that organizations only have a small group of simulation experts, making it unpractical to have direct access to simulation across the organizations. Luckily, this paradigm is changing. The rise of simulation apps, powered by multiphysics modeling, neural-network-driven surrogate models, and GPU acceleration, is democratizing access to advanced simulation. These easy-to-use applications extend the reach of simulation far beyond R&D, enabling teams in the field, on the factory floor, and in the boardroom to make real-time, physics-informed decisions. In other words, simulation apps are no longer just about engineering; they’re becoming indispensable business tools as well.

From Models to Apps: A Shift in Accessibility

The traditional workflow of simulation engineering has always been about precision. Whether focusing on a single physical phenomenon or coupling multiple domains together in multiphysics models, simulation engineers aim to capture reality as faithfully as possible. Single-physics simulations can provide excellent accuracy when one effect dominates, while multiphysics simulations enable engineers to include interacting effects for an even greater level of realism. Models are then validated with experiments and used to forecast behavior under a wide range of conditions, delivering confidence in their predictive power. With apps, validated models are encapsulated in streamlined interfaces, enabling users to simply enter parameters into intuitive fields (e.g., geometry, material properties, operating conditions) and receive precise results in real time. These apps make it possible for nonexperts to run analyses without needing to master finite element methods or specialized multiphysics software.

To give an example of how apps make simulation more accessible, an audio supplier for luxury car manufacturers ran into challenges with evaluating how design tweaks to car interiors affected in-cabin acoustics. The organization’s engineers built a custom app on top of their core acoustics model, and instead of waiting for the simulation specialists to rerun models, a global and cross-functional team was able to simply input design changes into the app and see how sound quality was impacted. This streamlined workflow eliminated delays across time zones and kept development aligned with fast-changing car designs.

Extending Simulation Beyond R&D

In various industries, simulation apps are increasingly being distributed across field operations, manufacturing, and even business management. For instance, one of the world’s largest suppliers of cement rolled out a simulation app for contractors that can help them decide on concrete curing times, a critical factor for both safety and profitability. The app integrates local weather data, soil conditions, and building geometry into a multiphysics model to predict curing timelines. With this app, contractors now make onsite decisions backed by physics, avoiding costly errors and delays.

Simulation apps are also being used in power grid maintenance. For instance, a utility company built an app for field technicians diagnosing cable failures. Instead of calling in simulation engineers or guessing based on limited test data, technicians input onsite observations into an app powered by multiphysics models. The app evaluates environmental and material factors in real time, enabling faster and more accurate troubleshooting and repair.

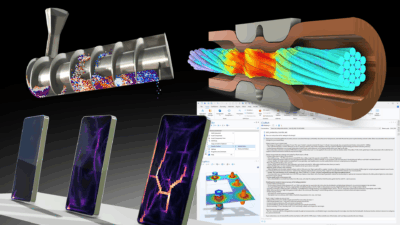

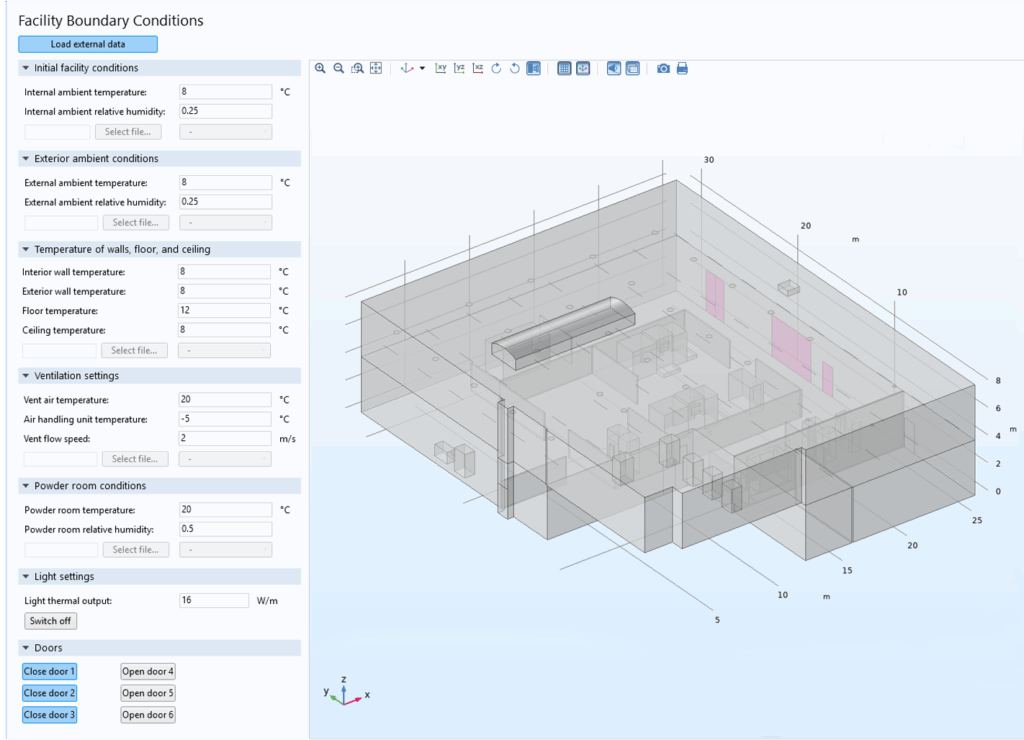

Let’s now consider additive manufacturing facilities. Factories that produce parts via metal powder bed fusion face challenges with humidity and heat control. Poor conditions not only compromise part quality but also pose safety risks due to the flammable nature of metal powders. A U.K. manufacturer built a simulation app to model its factory layout, incorporating variables like outside climate, machine placement, and operational schedules. Factory managers use the app to adjust ventilation and workflows in a way that keeps optimal production quality and worker safety in mind.

A simulation app for predicting the conditions of an additive manufacturing facility. Image courtesy of MTC.

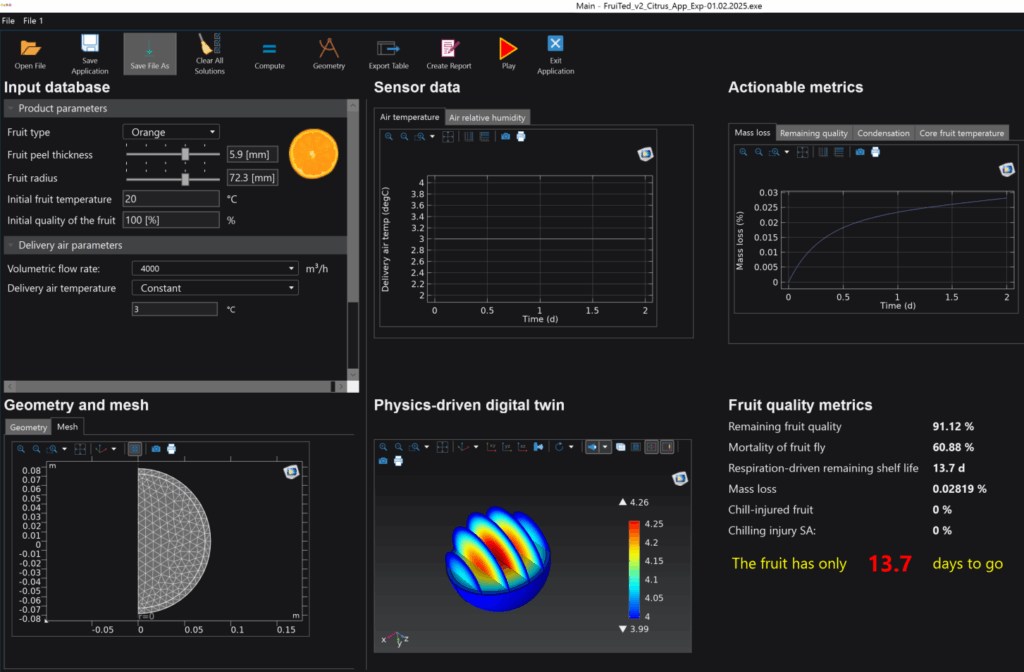

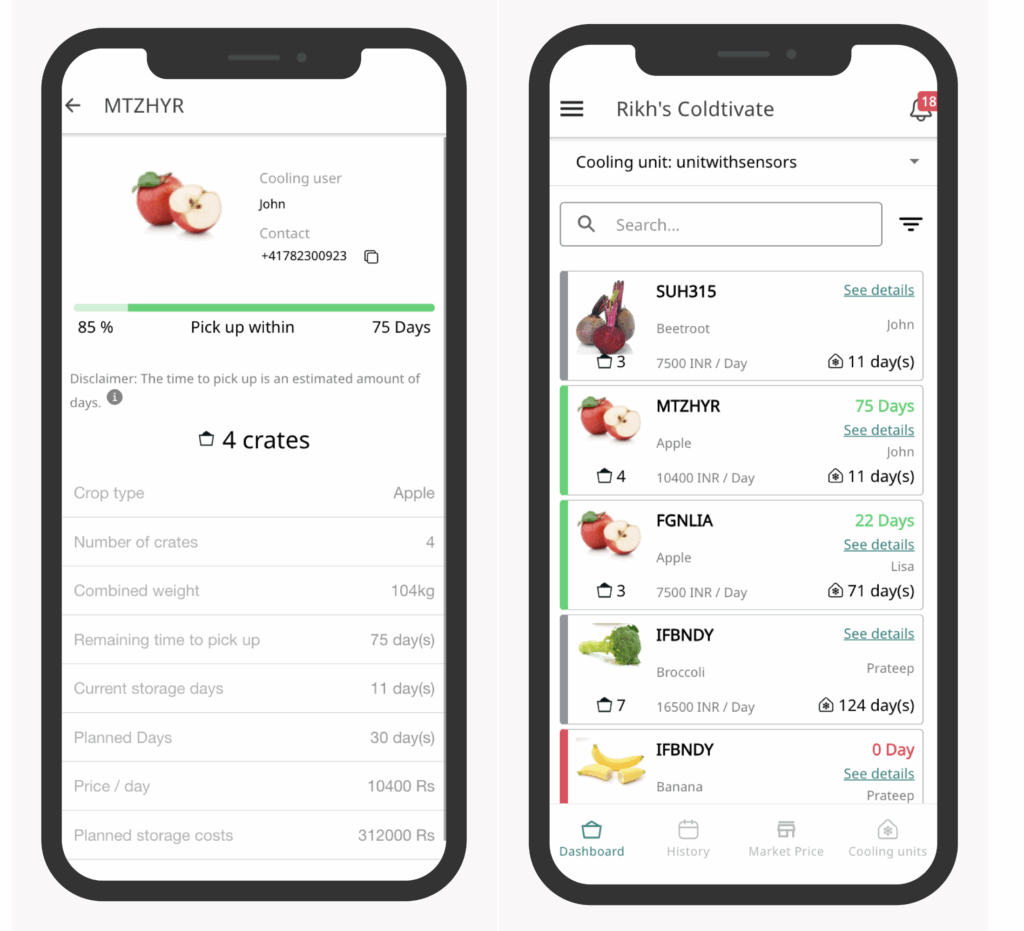

Another area where apps are being used is in the global food supply chain, where cold room managers face constant challenges around limited refrigeration space and food spoilage. A Swiss-led consortium used multiphysics simulation to predict fruit shelf life based on size, peel thickness, and storage conditions. The resulting mobile app provided real-time guidance to farmers and managers in rural India, cutting post-harvest food losses by 20% and boosting farmer income by the same margin.

An app forecasting fruit freshness based on multiphysics (left) and a mobile app offering insight into the expected shelf life of a crate in storage (right) based on science and real-time information. Image courtesy of Empa.

The Role of Surrogate Models

While simulation apps are powerful, running detailed multiphysics models in real time can still be computationally expensive. This is where surrogate models, often built using neural networks or other machine-learning-based reduced-order modeling techniques, benefit workflows.

Surrogate models act as lightweight stand-ins for full-scale physics solvers. They are trained on data from high-fidelity simulations and experiments and approximate the input–output behavior of the underlying model with high accuracy. Once trained, these reduced models can run thousands of times faster than traditional solvers, enabling near-instant predictions inside apps. For example, a transformer design team may need to explore hundreds of material and geometry combinations. Instead of waiting hours per simulation, a surrogate model embedded in their app can deliver results in seconds.

Harnessing GPU Acceleration

Another enabler of advancements in simulation is GPU acceleration. GPUs are designed for massively parallel computations, which map naturally onto the numerical solvers used in simulation. Simulation usually involve solving equations in millions of variables, and GPUs provide significant speedups over CPU-only computations.

For simulation apps, GPU acceleration means:

- Real-time interactivity: Users can adjust parameters and instantly see updated results, even for complex multiphysics models.

- Scalable deployment: Apps can be hosted on GPU-accelerated cloud platforms, allowing global teams to access powerful simulation capabilities without investing in high-performance local hardware.

- Support for hybrid workflows: GPU acceleration combined with surrogate models makes it possible for apps to dynamically switch between high-fidelity physics and fast approximations depending on user needs.

Simulation as a Business Tool

Looking at the business side of innovation, traditional systems rely on statistical models or linear equations to optimize inventory, scheduling, or financial planning. Apps extend this concept by embedding the fundamental laws of physics and chemistry into the decision-making framework. The result is unprecedented realism in forecasts and recommendations. For instance, rather than asking “What parts of this system do we need to change in order to minimize cost?”, business teams can ask, “How will humidity, airflow, and material properties affect part quality, cost, and safety?” Apps provide answers that account for real-world complexity, helping organizations minimize risk, accelerate innovation, and maximize performance.

Looking Ahead

The convergence of multiphysics modeling, surrogate models, and GPU acceleration is ushering in a new era of simulation. No longer siloed within R&D, simulation apps are growing as everyday tools across teams and departments.

To summarize the business implications of these tools, we will see:

- Faster time to market through accelerated design iteration

- Lower costs thanks to a reduced need for physical prototypes and postproduction fixes

- Broader adoption of simulation by empowering nonexperts to make physics-informed decisions

In short, simulation apps ensure that organizations can keep pace with an ever-changing world and enable smarter and faster decisions everywhere business happens.

Sponsored Content by Comsol