Immersive Engineering provides an intuitive environment for designers to assess geometry, ergonomics and assembly intent.

Siemens has sponsored this post.

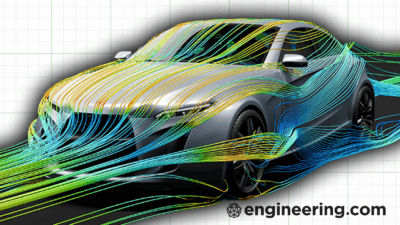

Traditional CAD tools have always been constrained by flat screens, 2D interactions and limited spatial feedback. Engineers interpreting complex geometry through a monitor often struggle to judge scale, evaluate fit and identify interferences. As products grow more complex, these limitations push decisions later into the design cycle and shift many errors downstream into physical prototyping.

“Engineers can zoom in indefinitely within a 3D CAD setting, but that also means you can quickly lose perspective on what you’re looking at. As a result, design flaws remain hidden until physical prototypes are built, whether you’re working on boats, airplanes and cars, or on compact consumer electronics,” says Ben Widdowson, Head of Marketing Immersive Engineering at Siemens.

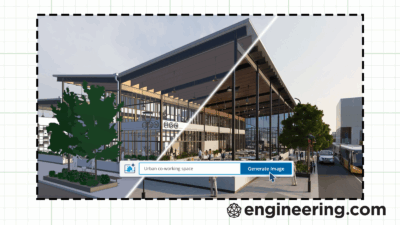

Immersive Engineering solves these challenges by providing an intuitive environment for designers to assess geometry, ergonomics and assembly intent. Siemens is among the first to integrate Immersive Engineering and AI-driven assistance into a mainstream CAD environment through its Designcenter NX platform.

Siemens AI-enhanced Immersive Engineering platform

Siemens has long been integrating immersive capabilities as an optional module into its Designcenter NX platform. It transforms product development from a visual add-on to a fully operational engineering environment. The Immersive Designer lets users open assemblies at a true scale, modify geometry and collaborate with remote teams.

A major enabler is the purpose-built Sony XR headset designed specifically for engineering workflows. “Sony built a mixed-reality headset specifically for engineering workflows that focuses on all-day comfort, ultra-high-resolution displays and controllers tailored for precision work,” Widdowson adds.

This integration addresses one of the most significant gaps in earlier generations of VR tools: the inability to perform real engineering tasks. Siemens’ approach treats immersiveness as an alternate mode of CAD, and not an isolated experience. “Users can do everything they would normally do on a desktop, but fully immersive and collaborate in real-time,” Widdowson explains.

AI adds another dimension to this environment. Siemens is developing a foundational engineering model capable of interpreting 3D geometry, design intent, bills of materials and manufacturing rules. These are some of the areas where generic LLMs like ChatGPT and Gemini have limited understanding.

This underpins tools like NX Copilot for natural language assistance, automated DFM (Design for Manufacturing) advisors that flag manufacturing issues and ML-based productivity features such as adaptive UI and selection prediction.

“We’re developing our own foundational model that can connect to LLMs while teaching them the language of engineering. It allows AI to understand a customer’s specific products and processes, while drawing on Siemens’ aggregated industry knowledge and the broader capabilities of public models,” Widdowson notes.

Case Study: BAC Mono Supercar

The immersive tools are already in use. Briggs Automotive Company (BAC), the boutique British automaker behind the Mono supercar, demonstrates how Immersive Engineering accelerates real-world product development. As they engineer the next-generation Mono, the team uses NX Immersive Designer to evaluate and refine cockpit ergonomics, packaging and regulatory compliance.

By putting on the Sony headset, BAC designers can sit in a virtual driver’s seat and see the cockpit exactly as a driver would. They can test reach, visibility, pedal comfort, steering-wheel positioning and spatial feel with full-scale accuracy. One standout use case is the ability to reposition interior components on the fly in an immersive setting.

Designers can move the steering wheel, adjust seat geometry or reposition the pedals using the hand controllers. At the same time, other experts such as ergonomists, manufacturing engineers and regulatory reviewers, can join the same immersive session. This collaborative environment is important for navigating global compliance requirements.

“They had to meet a wide range of global regulations, so they described a design review where designers, engineers and even manufacturing stakeholders all joined the same immersive session. They evaluated something as simple as headlight placement, and whether it still meets regulations, without anyone needing CAD expertise,” says Widdowson.

Conclusion

Immersive Engineering is far more than a flashy new way to look at models. It is proving to be a transformative technology that, when combined with AI, can compress development cycles, reduce errors, and improve collaboration across the product lifecycle. The Siemens Designcenter NX integration with the Sony XR headset shows how Immersive Engineering is being used in real workflows.

“Our view is that in ten years, Immersive Engineering won’t be a new capability at all. It will simply be the way engineers work, just as naturally as using a desktop today. Our customers build everything from smartphones to airplanes. As the next generation of engineers enters the workforce, we see it as our responsibility to make engineering more exciting, intuitive and engaging,” Widdowson concludes.

Visit Siemens to learn more about Immersive Engineering with NX CAD.