Xi’an Bright Laser Technologies follows up on US distribution agreement with GoEngineer, focusing on emerging markets in Malaysia and South Africa.

(IMAGE: BLT)

The growth of the Chinese additive manufacturing (AM) industry over the past few years has been a hot topic of conversation among industry insiders.

The additive manufacturing consultancy AM Power put China’s AM market at a compound annual growth rate (CAGR) of 27% over the last five years, which is apparently more than twice the global average of 12%.

Meanwhile, the market intelligence firm CONTEXT reported last year that sales of Chinese metal AM systems – particularly laser powder bed fusion (L-PBF) – were up 45% year-over-year, while Western sales of metal L-PBF systems were down 4% in the same period.

On the ground, one needs only look back on the exhibitor maps of major industry shows, such as RAPID+TCT or Formnext, over the past few years to see the swelling number of Chinese AM suppliers and the growing footprint of many booths.

While talk of the growth of 3D printing in China often focuses on the consumer market with companies such as Bambu Lab or Creality, as the CONTEXT stats show, the industrial AM sector is also expanding quickly.

Take Xi’an Bright Laser Technologies (BLT) as an example.

This year alone, BLT has announced three major distribution agreements, the biggest with engineering solutions provider GoEngineer for sales in North America in March. More recently, BLT also announced partnerships with Malaysian GSH Precision Technology – a provider of fabrication, contract manufacturing and industrial automation – as well as South African AMT3D, which also acts as a re-seller for Meltio and MX3D metal AM machines in sub-Saharan Africa.

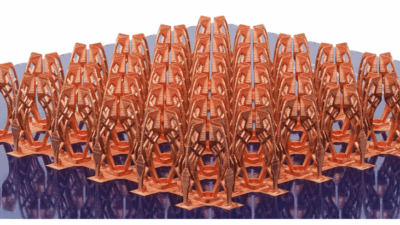

Add in BLT Europe, the company’s Frankfurt-based subsidiary, which boasts “over 1,400 installed metal machines and counting” on its LinkedIn page, and you’ve got an impressive global distribution network for a company that didn’t even exist 15 years ago. As to where this is all heading, you only need to look at what BLT chose to highlight during this year’s Formnext: a copper inner wall liner for a rocket engine thrust chamber.

3D printed on a six-laser BLT-S615 using copper-chromium-zirconium powder, the part measures an impressive 502mm x 946mm and weighs 35 kg. Copper powders are notoriously difficult to print using L-PBF owing to the material’s reflectivity, which makes this an ideal candidate to demonstrate BLT’s technical capabilities.

The choice of industry application seems fitting as well, given the increasing emphasis and interest in South Africa’s aerospace industry, plus the recent investment by GE Aerospace (which owns BLT competitor Colibrium) in Malaysian aerospace and aviation training. Partnering with an American re-seller like GoEngineer is an obvious move for BLT to expand in the near-term, but these partnerships with GSH and AMT3D show that the company is playing the long game, too.