Announcements from BLT and Colibrium, PLUS winners of the 2025 Formnext Awards.

Welcome to Day 3 of my remote coverage of Formnext 2025!

(Here’s Day 1, here’s Day 2, and here’s live footage of the Frankfurt Airport so you can create your own virtual travel experience.)

Let’s start with a couple of announcements.

BLT’s AI quality software

I thought I might be able to get away with not talking about AI for the duration of the show but I’ve been foiled by my own hubris and also the latest piece of software from Bright Laser Technologies, aka BLT.

Designed for metal laser powder bed fusion (L-PBF), BLT-PrintInsight combines online monitoring and offline analysis to provide process visibility, control, and traceability in additive manufacturing (AM). According to the company, the software uses multi-source data fusion and (offline?) AI-driven analysis to provide real-time defect detection and feedback as well as post-process risk assessment.

The online monitoring module aims to automate defect recognition and correction using vision algorithms to reduce human effort and improve detection accuracy. Key functions cited by BLT include powder spreading online monitoring and scanning online monitoring. The former is designed to detect powder shortages, uneven powder spreading, collapse, and recoater collision, while the latter is built to identify burnt spots and slag buildup.

The offline analysis module uses post-print data to evaluate part quality and pinpoint risk areas, combining 3D model visualization, defect record management, and one-click quality report generation.

As upgrades, users can also customize detection models using their own defect samples, capture real-time thermal radiation signals to generate thermographic maps, or incorporate video recording with support for playback and automatic cleanup.

Commercial availability of new Colibrium M Line L-PBF machine

GE Aerospace subsidiary Colibrium Additive has announced the commercial availability of its new M Line 4 × 1 kW laser powder bed fusion (L-PBF) system, designed for the production of complex components in aerospace and defense.

Building on the company’s M Line 4 × 400 W platform, the new system is intended to deliver a significant increase in productivity via higher laser power and features a 500 × 500 × 400 mm build volume.

“The M Line 4 × 1 kW system allows manufacturers to accelerate productivity without sacrificing quality,” said Philipp Schumann, Product Manager – M Line at Colibrium Additive in a press release. “It meets the rising demand, especially in highly regulated industries, for faster, more cost-effective production by combining precision where it matters most with efficiency across the rest of the part.”

According to the company, the M Line 4 × 1 kW system supports CoCr and Ni718 materials at launch, with additional parameters currently under development. All parameters are visible and editable within the WRX3 software suite, which also provides open access to sensor and operational data streams through an OPC/UA interface.

The M Line platform incorporates a modular architecture that separates the Laser Processing System (LPS) from the Material Handling Station (MHS). This configuration is intended to enable powder resupply, part removal, or other handling tasks to run in parallel with active printing.

2025 Formnext Award Winners

I’ll have more details about some of the organizations and individuals listed below in a future article but, for now, here’s a quick rundown of this year’s award winners.

AMbassador Award: Irena Heuzeroth, research associate and trainer, SKZ

An engineer and senior AM trainer in the field of injection molding, Irena has been very involved in the practical study course “Certified Industrial Technician Specializing in Additive Manufacturing,” which is offered jointly by the Würzburg-Schweinfurt Chamber of Industry and Commerce and SKZ.

Design Award: Hochschule für Gestaltung Schwäbisch Gmünd

A German university of applied sciences for design, HfG Schwäbisch Gmünd won for its Grabbit products, which are made from TPU lattice structures, PA12, and ash wood. They’re designed to help with hand strength and dexterity in cases of illness, injury, or age-related weakness.

(R)Evolution Award: Laempe Mössner Sinto

A supplier of foundry solutions for core making, LMS won for its 3D printing system for the large-scale production of sand cores, currently in operation at BMW Group. The system produces over 1,100 cores per day, which makes it one of the fastest binder jetting printers in the world.

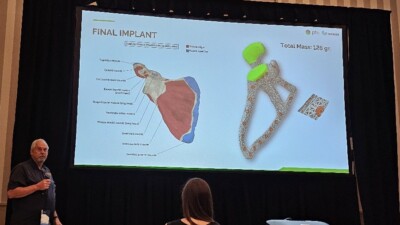

Rookie Award: IAM3DHUB

The international advanced manufacturing consortium won for its 3DMyMask project, which combines AM with 3D face scanning to produce customized silicone masks designed to improve the treatment of disorders such as respiratory distress. The project includes neonatologists, industrial engineers, and entrepreneurs, all of whom are part of the IAM3DHUB ecosystem.

Start-up Award: PERFI Technologies

Winning for its volumetric additive manufacturing (VAM) technology, the company is aiming to transform conventional 3D printing by printing every point of an object simultaneously, rather than layer by layer. If it works, this would reduce production times from hours to seconds, as well as obviating support structures and reducing post processing.

Sustainability Award: EOS Electro Optical Systems

EOS has developed a filter system designed to neutralize condensate, soot, ultra-fine particles, and other reactive by-products of metal-based AM directly in the production process, converting highly reactive particles into stable metal oxides. According to EOS, this chemical-free filtration and integrated oxidation technology not only protects the environment, it’s also economically sustainable.

That’s all for today. See you tomorrow for my show wrap-up and retrospective.