Dassault and Materialise added to the company’s growing list of industry partners.

The RenAM 500Q Ultra is a laser powder bed fusion (L-PBF) system for metal additive manufacturing, available with single, dual, or quad lasers. (IMAGE: Renishaw)

Like castells or underwater hockey, additive manufacturing (AM) is a team sport: success in 3D printing on an industrial scale requires collaboration and input from experts across multiple domains. Examples abound, from consortiums of the largest 3D printing companies, to research projects between Ivy League rivals, to joint efforts between public and private institutions on materials discovery.

Three of the latest examples of this trend originate with one company: Renishaw.

Hot on the heels of its participation in a new metal AM project spearheaded by Airbus, the British engineering company has announced collaborations with the French Dassault Systèmes and the Belgian Materialise, portending significant growth in European AM collaboration (Brexit notwithstanding).

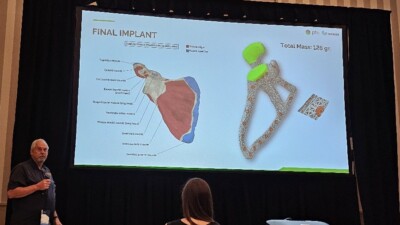

RenAM 500 series now integrated into 3DExperience

According to a recent press release from Renishaw, users of the 3DExperience Delmia Powder Bed Machine Programmer Role can now set-up, program, and analyze AM processes for Renishaw 500 series metal AM systems.

“A virtual machine is an exact representation of a machine in the virtual world, with all its parameters. You can launch a production run and make virtual parts; it’s unique in terms of quality validation,” said Jérémy Mosse, team & application manager at Dassault Systèmes, in the release.

This role provides a 3D interactive environment that’s intended to enable manufacturing engineers to optimize powder bed fusion manufacturing techniques, and it includes Renishaw’s TEMPUS technology, which is designed to allow the machine’s laser to operate while the recoater is in motion. Renishaw claims this can result in time savings of up to nine seconds per build layer without compromising part quality, reducing overall build times by as much as 50%.

“This collaboration enables a unique approach to efficient metal 3D printing,” said Olivier Scart, DELMIA alliances director partnerships at Dassault Systèmes, in the same release. “The combination of Renishaw’s TEMPUS technology and the end-to-end unique solution provided by the 3DExperience platform will break silos and open a new stage for additive manufacturing industrialization.”

Highlighted benefits of the integration, according to Renishaw, include part validation prior to 3D printing, part simulation of the AM process to explore machine parameters virtually, and part traceability between design and manufacturing.

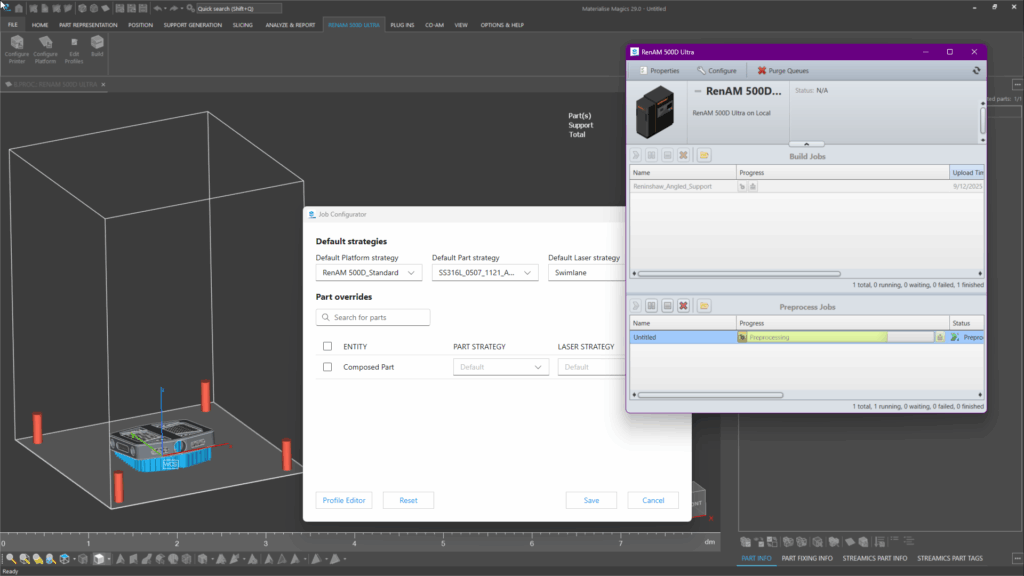

Next-generation Build Processor software with Materialise

In addition to its integration with 3DExperience, Renishaw has also announced the launch of next-generation Build Processor (NxG BP) software developed in collaboration with Materialise. The new software aims to strengthen integration between Materialise Magics and Renishaw’s RenAM metal AM systems by enabling the direct export of job files from Magics to Renishaw machines using the QuantAM file format.

“We’ve worked closely with users to understand where the bottlenecks are in their AM workflows,” said Ben Diaz, product manager at Renishaw, in a press release. “NxG BP enables swim lane laser control, integrated inspector tools, implicit modelling support and compatibility with the RenAM 500 series of machines. Ultimately, customers will have a more intuitive and efficient way to get from design to print.”

According to Renishaw, a key innovation in the software is the Swim Lane feature, which is designed to distributes laser scanning intelligently across defined regions of the build platform.

“By enabling direct integration between Magics and Renishaw systems, we’re removing the friction that slows down advanced users who are pushing the boundaries of what’s possible with metal 3D printing,” said Karel Brans, partnership director at Materialise, in the same release. “Whether it’s handling complex implicit geometries or optimizing multi-laser performance with features like swim lane control, this collaboration gives Renishaw customers the workflow control they need to succeed on their terms.”

NxG BP also incorporates an integrated Inspector tool for real-time verification of laser paths and job setup directly within the workflow. The processor is fully compatible with the complete RenAM machine range and is intended for advanced AM “power users” who manage a wide variety of part types and need functionality that goes beyond QuantAM per se.

Stay tuned for lots more AM news this week as Formnext 2025 kicks off in Frankfurt.

Here’s a taste of what you can expect from the show.